PRODUCT

Rotomolding Powder Types

LLDPE Rotomolding Powder

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Velit est facilis maiores.

Read More

Virgin Rotomolding Powder

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Velit est facilis maiores.

Read More

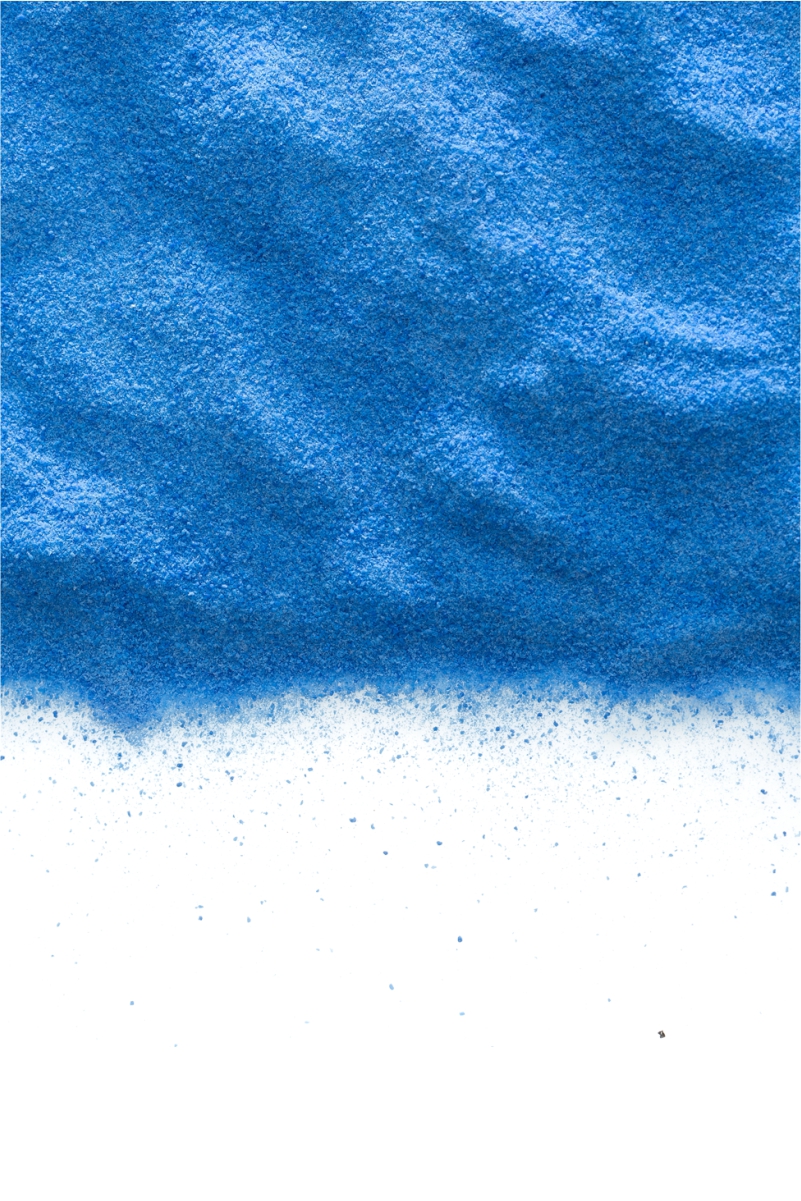

Blue Rotomolding Powder

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Velit est facilis maiores.

Read More

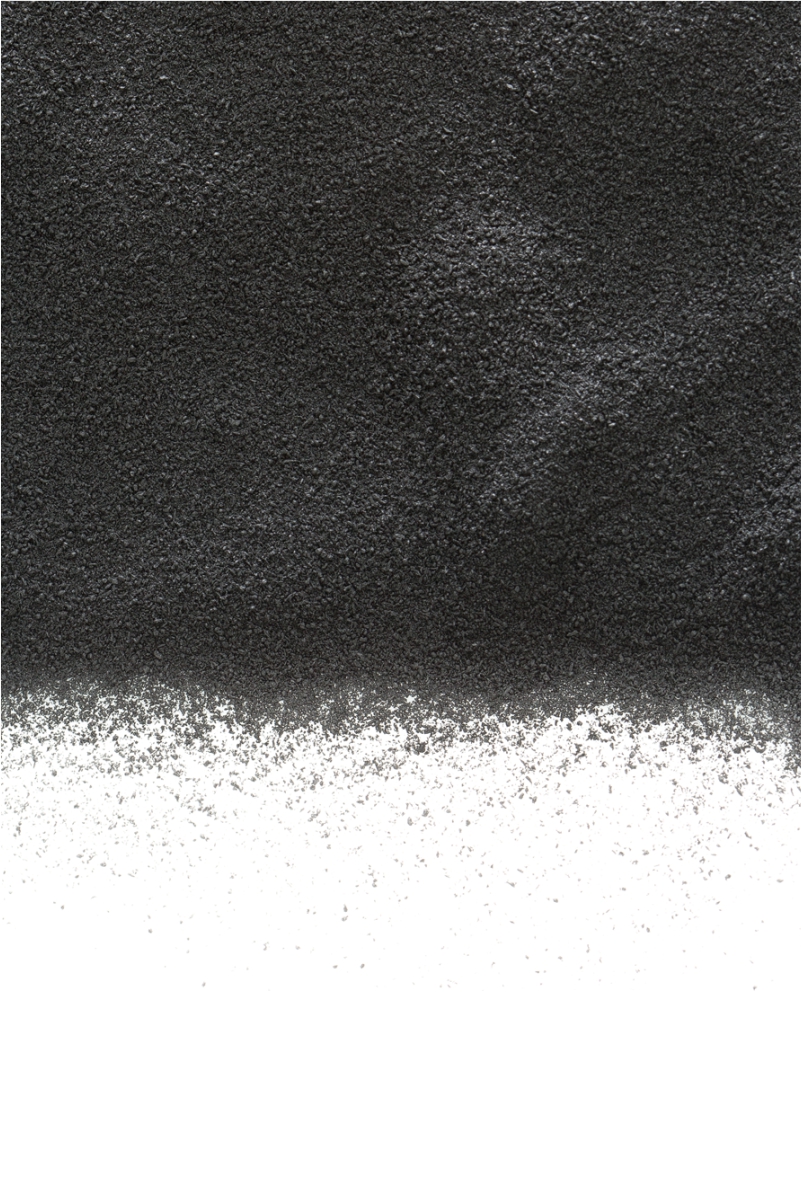

Black Rotomolding Powder

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Velit est facilis maiores.

Read More

Rotomolding Pulverised Powder

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Velit est facilis maiores.

Read More

UV Rotomolding Powder

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Velit est facilis maiores.

Read MoreGrades of GreenEthene

Grading of GreenEthene powders is based on density, melt flow, impact resistance, rigidity, ESCR (Environmental Stress Crack Resistance), grind type and custom compound colors.

| grade | Density (gm/cm3) | mfi (gm/10 Mins) | Tensile strength (Mpa) | impace strength (kg.cm/cm) | Characteristics | typical Application |

|---|---|---|---|---|---|---|

| Ge3645 | 0.936 | 4.5 | 18 | 25 | Good stiffness, high processign speed, impact strengh & ESCR | General moulding, Medium sized tanks & fuel tanks |

| Ge3938 | 0.939 | 3.8 | 21 | 22 | Flexible very high ESCR & impact strenght | Large tank for water, IBCS, floats and bins |

| Ge3904 | 0.939 | 4 | 20 | 50 | Hexene Co-polymer based, Excellent impact Strenght with surface finish & fast cycle time | Low temperature service parts, parts that require precise dimention or less tolerance |

| Ge3804 | 0.938 | 4 | 20 | ARM 19 | High glow, long durability, fair impact resistance. | General purpose products, drums, container and pallets. |

PACKAGING

Packaging is done in specialized laminated sacks to ensure their damage free and contamination free transportation. Clear labelling of the products along with sample pouches facilitates the customers to keep a record of the delivered batches. No extra price for samples or trials is charged.

Lead Time Required

Lead Time required for stocked powder is around 3 days and for production is 5 days. Immediate orders for custom colour and production can also be carried out on demand.